◆ Definition

A

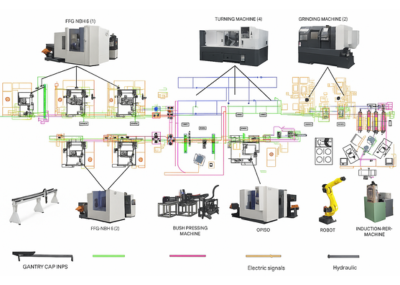

Turn Key System refers to a one-stop solution provided by the equipment

supplier, covering everything from planning and design to manufacturing,

integration, installation, and acceptance testing. Customers only need to

define their production requirements, and the supplier delivers a fully

functional production line — ready to operate by simply “turning the key.”

Features

l One-Stop

Integration: Covers planning,

design, manufacturing, installation, testing, and training, eliminating the

hassle of coordinating multiple suppliers.

l Fast

Implementation: Shortens setup time,

enabling customers to quickly ramp up to mass production.

l Customized

Design: Tailored to industry

characteristics, product specifications, and production capacity requirements.

l High

Efficiency & Stability:

Ensures seamless coordination between equipment, improving productivity and

product consistency.

l Risk

Reduction: Managed entirely by

professional teams to minimize integration errors and investment risks.

l After-Sales

Support: Includes training,

maintenance, and technical support to ensure long-term system reliability.

Application

Turn Key Systems are especially suitable for

industries requiring large-scale, fully automated production, such as

automotive parts, aerospace, precision machinery, and electronics. They help

manufacturers rapidly build smart production lines to achieve high efficiency

and stronger competitiveness.