◆ Definition

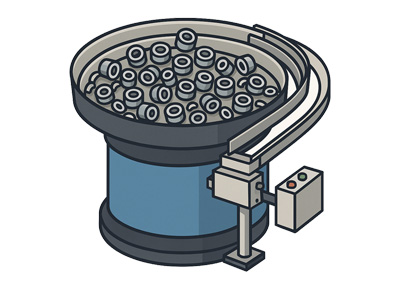

The

automatic parts feeder is an essential component of a smart manufacturing

production line. It enables automated, continuous, and precise delivery of

workpieces to machining equipment, replacing manual handling and significantly

improving production efficiency and stability. With its flexible design, the

feeder can be customized according to the size, shape, and weight of the

workpieces, and seamlessly integrated with CNC machine tools or automated

production systems.

Features

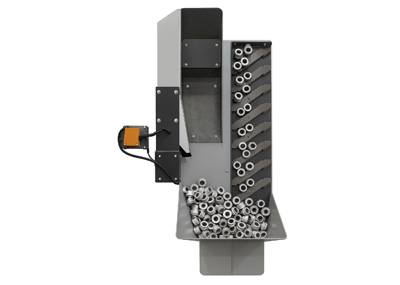

l Stable

Feeding: Ensures continuous

supply of workpieces, reducing downtime.

l Accurate

Positioning: Equipped with sensors

and control systems to guarantee precise positioning before machining.

l Efficiency

Boost: Supports long hours

of automated operation, reducing manpower requirements.

l Flexible

Application: Suitable for various

workpiece specifications, meeting diverse machining needs.

l Safety

Design: Integrated with

protective mechanisms to enhance operational safety.

Application

The Automatic Parts

Feeder enables continuous production, consistent quality, and reduced labor

costs. It is particularly valuable in addressing labor shortages and

high-efficiency demands, making it an essential module in smart manufacturing

production lines.